Foam Packaging Materials & Capabilities

Morrisette Packaging now offers Foam Conversion as part of our packaging solutions.

In this blog we will share deeper details with you on how Morrisette Packaging can unbox your packaging potential through:

- Custom Foam Fabrication

- Protective Foam Packaging

- Specialized Foam Components

- Custom Foam Inserts

- Precision Die-cutting

- Slitting and Skiving

- CNC Routing

- Turnkey Assemblies and Kitting

- PE Foam

- Polyurethane Foam

- Crosslink Foam

- Soft and Rigid Foam Materials

At Morrisette Packaging, we specialize in enhancing the safety and presentation of your products with our innovative and comprehensive packaging solutions.

How do Morrisette Packaging’s foam fabrication services set us apart?

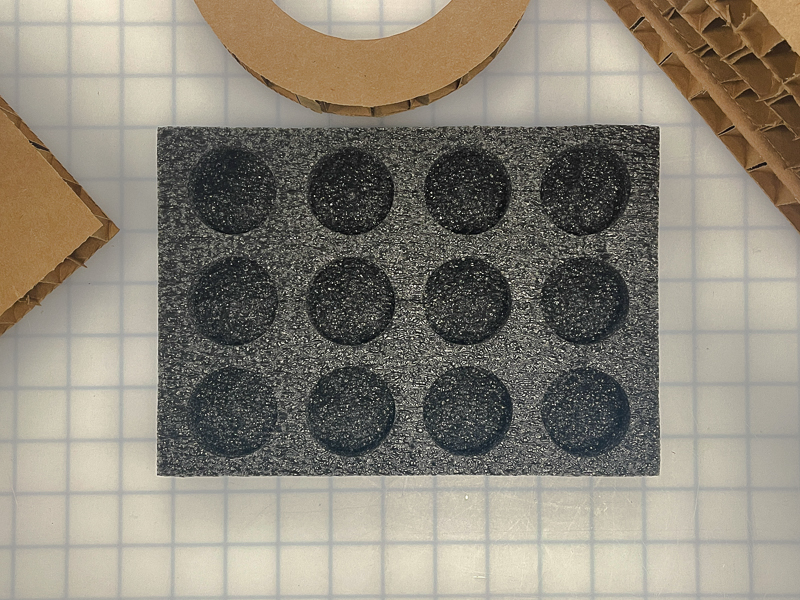

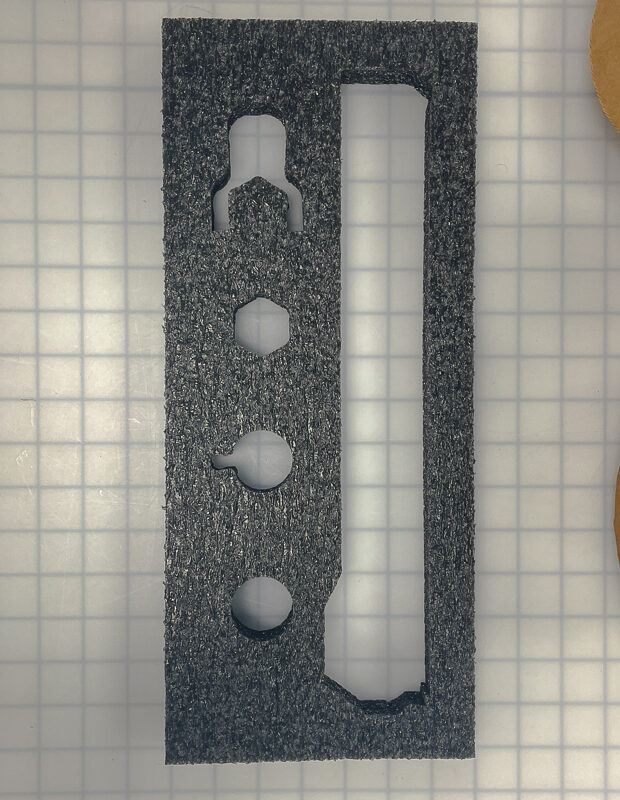

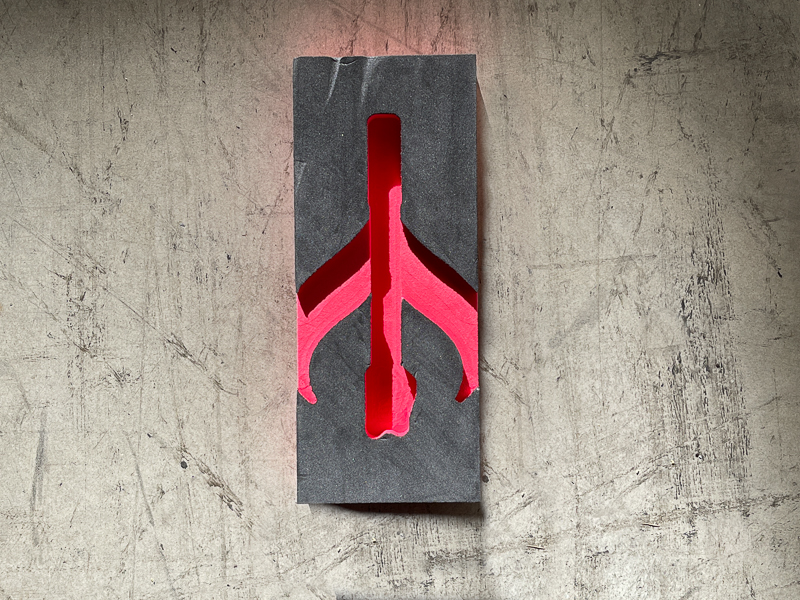

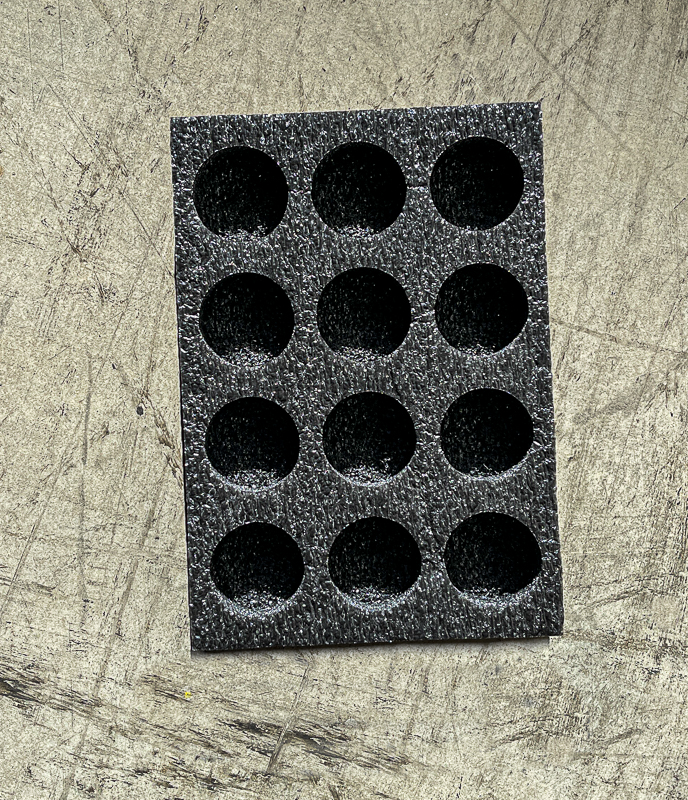

With our advanced foam fabrication technologies, we can create custom foam inserts, specialty packaging, and foam components to meet your exact needs.

Our machinery is 90% automated, reducing human error and increasing the quality and reliability of our products.

We are committed to providing an excellent range of foam-converting capabilities, including precision die-cutting, laminating, slitting and skiving, CNC routing, turnkey assemblies, and kitting.

Morrisette Packaging can cater to various industries such as automotive, aerospace, firearms packaging, military, contract electronics, upholstery and specialty packaging.

We can fabricate different foam types, including PE, Polyurethane, and Crosslink foams, which allows us to provide tailored packaging solutions based on our clients’ specific needs.

Morrisette Packaging prides itself on prompt responses, cost-competitive pricing, and quick turnarounds. We offer a total solution approach with distinct advantages because we control every step of the production process.

Our experienced team designs foam solutions for different packaging needs, ensuring you get the most efficient and effective packaging solution available.

Superior die-cutting machines help fabricate soft and rigid materials, including Polyurethane, Polyethylene, Crosslink, and more. The CNC routing in Morrisette Packaging is highly customizable for small or large runs. We are unrivaled in quality and efficiency.

Our Foam Conversion services integrate seamlessly with our existing segments, from packaging design to kitting and fulfillment, helping us unbox your packaging potential from design to delivery.

Custom Foam Packaging Material

With our exceptional foam fabrication and packaging capabilities, Morrisette Packaging offers innovative and comprehensive packaging solutions, including:

- Fabrication of PE, Polyurethane, Crosslink, and other foam types

- 90% automated processes for consistent quality

- Strategic partnerships for a robust supply chain

- Precision die-cutting and laminating services

- Slitting, skiving, and CNC routing capabilities

- Highly customized assemblies and small-run production

- Turnkey assemblies and kitting services

- Industries served: Specialty Packaging, Automotive, Aerospace, Firearms packaging, Military, Contract electronics, Custom foam case inserts.

We are at the forefront of the latest packaging technologies, promising to deliver quality products that meet and exceed your expectations.

Our goal is to elevate your entire packaging experience by ensuring the safe and reliable transportation of products while enhancing your product visibility, marketing, and brand recognition.